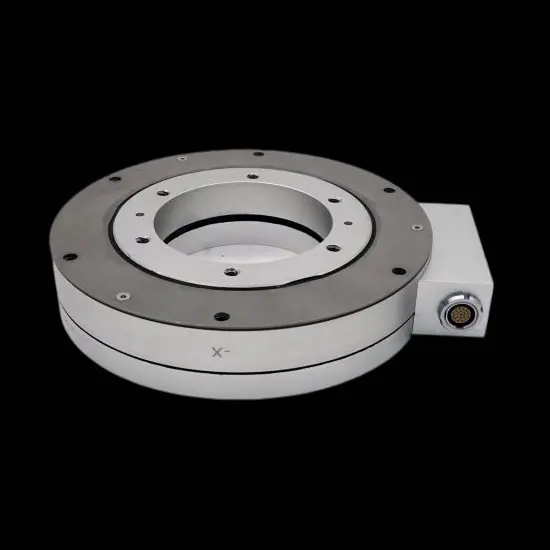

M66xx Series Torque Sensors

Maximum Flexibility

M66xx Series Sensor Details

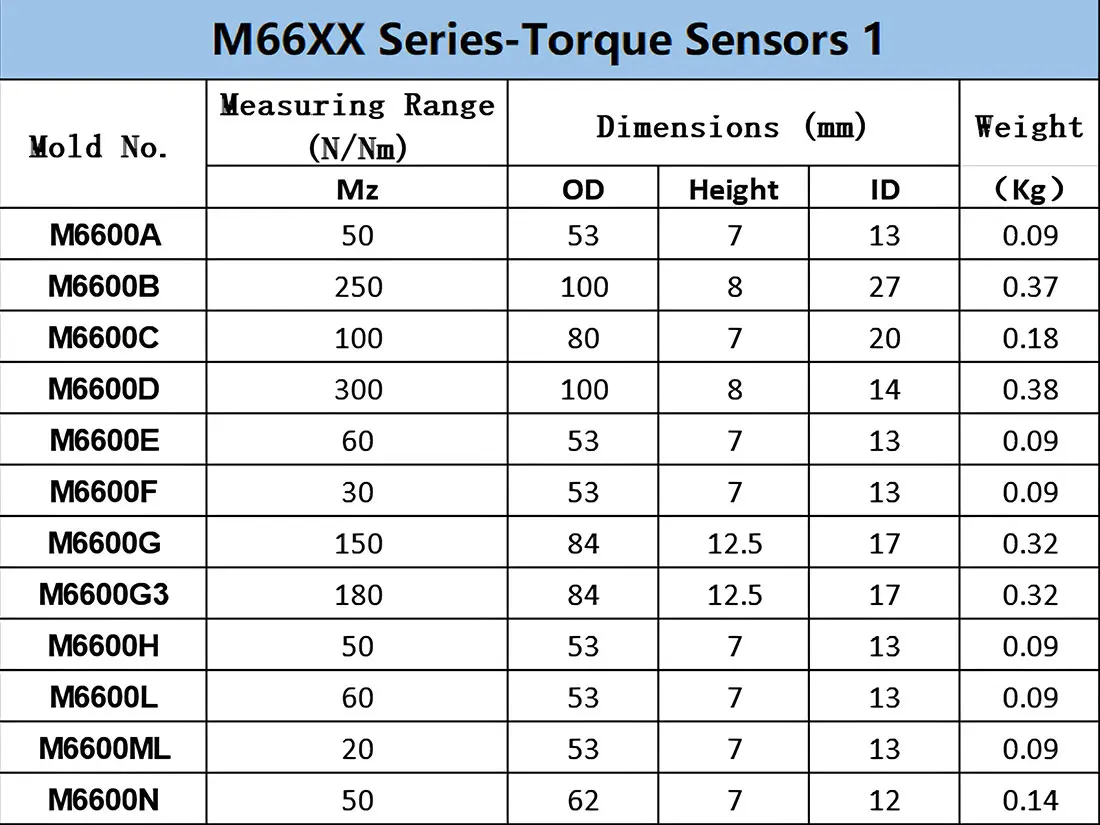

The M66xx series is a single-axis torque sensor designed for torque measurement in robotic joints. With a thickness as thin as 7mm and diameters ranging from 53mm to 100mm, it covers measuring ranges of 20Nm to 300Nm. The sensor features an integrated amplifier, operates on 5V DC input, and provides 0-5V analog output.

Model. Which is best for you?

Our engineers possess decades of experience in sensor customization, delivering bespoke solutions tailored to your specifications. By analyzing your requirements for measuring ranges, dimensions, and accuracy, we develop optimized product designs that ensure seamless integration across diverse applications.

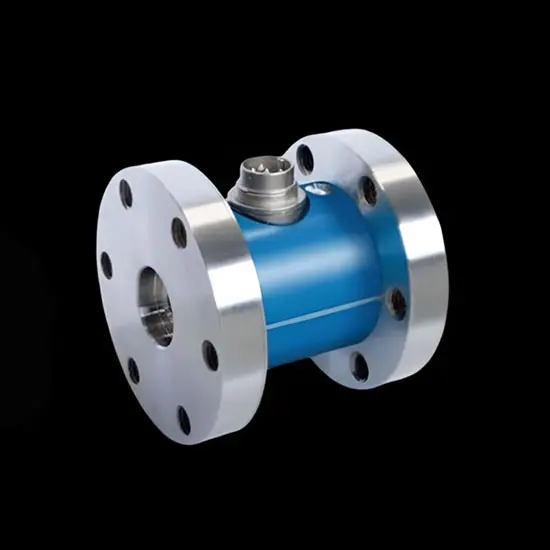

Torque Sensors

Customization Specialist

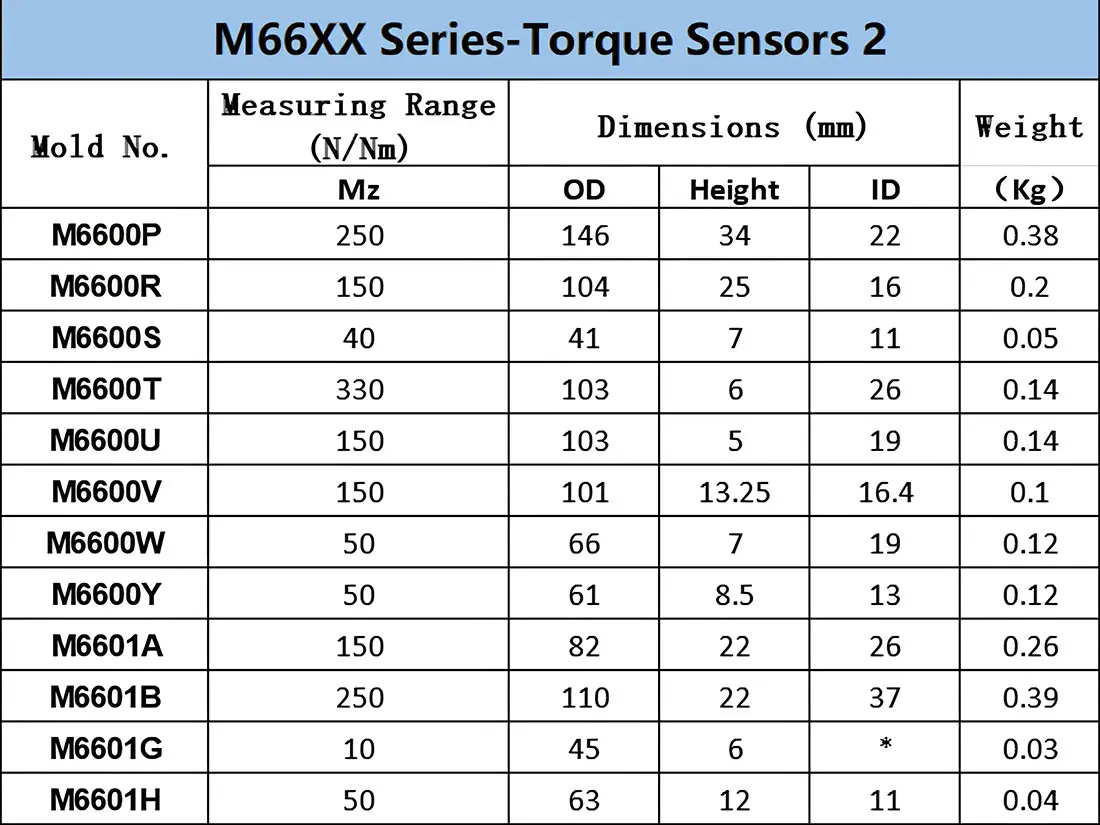

M66xx Series Products

MareX Sensor, Versatile Applications.

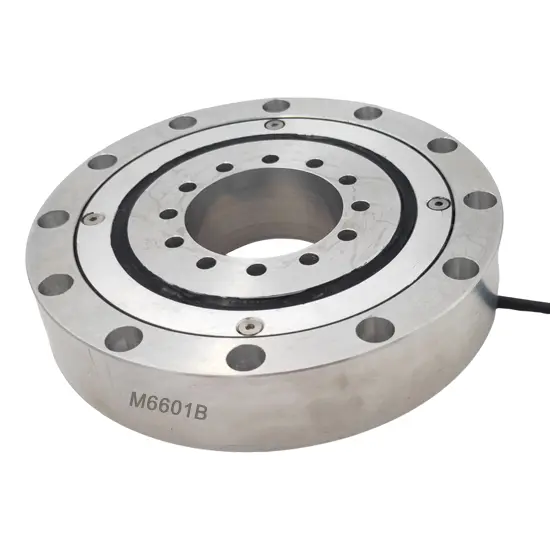

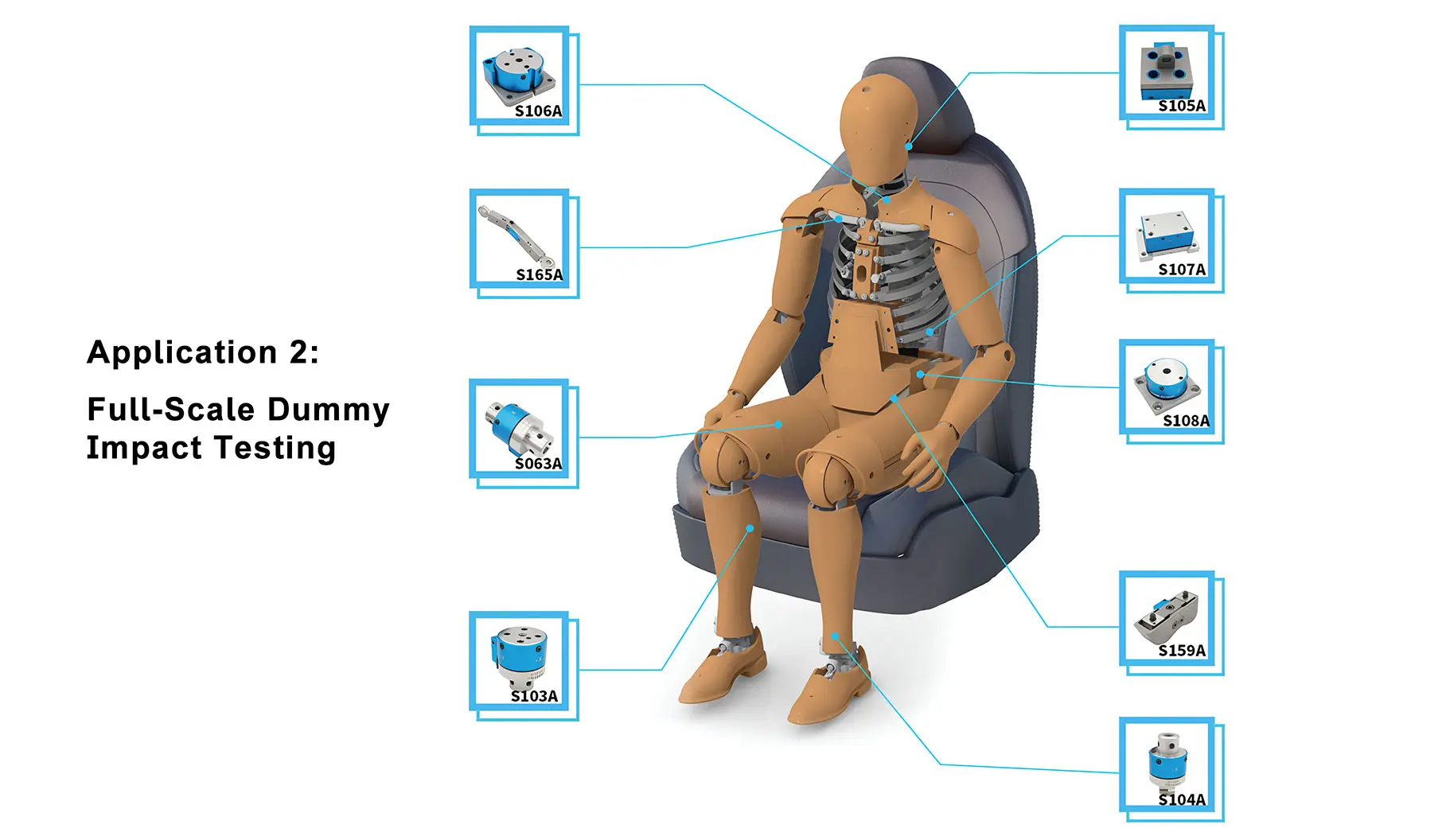

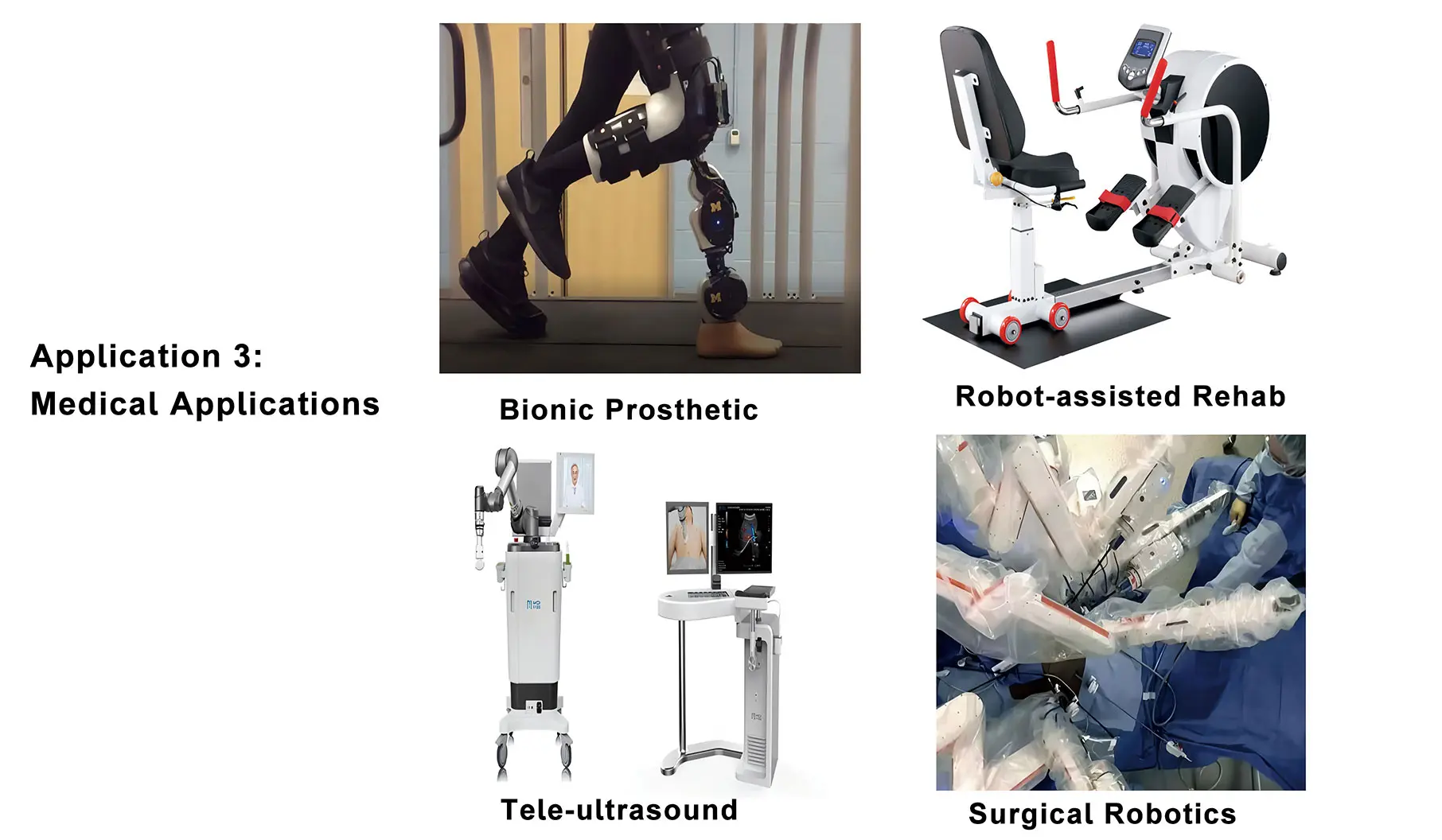

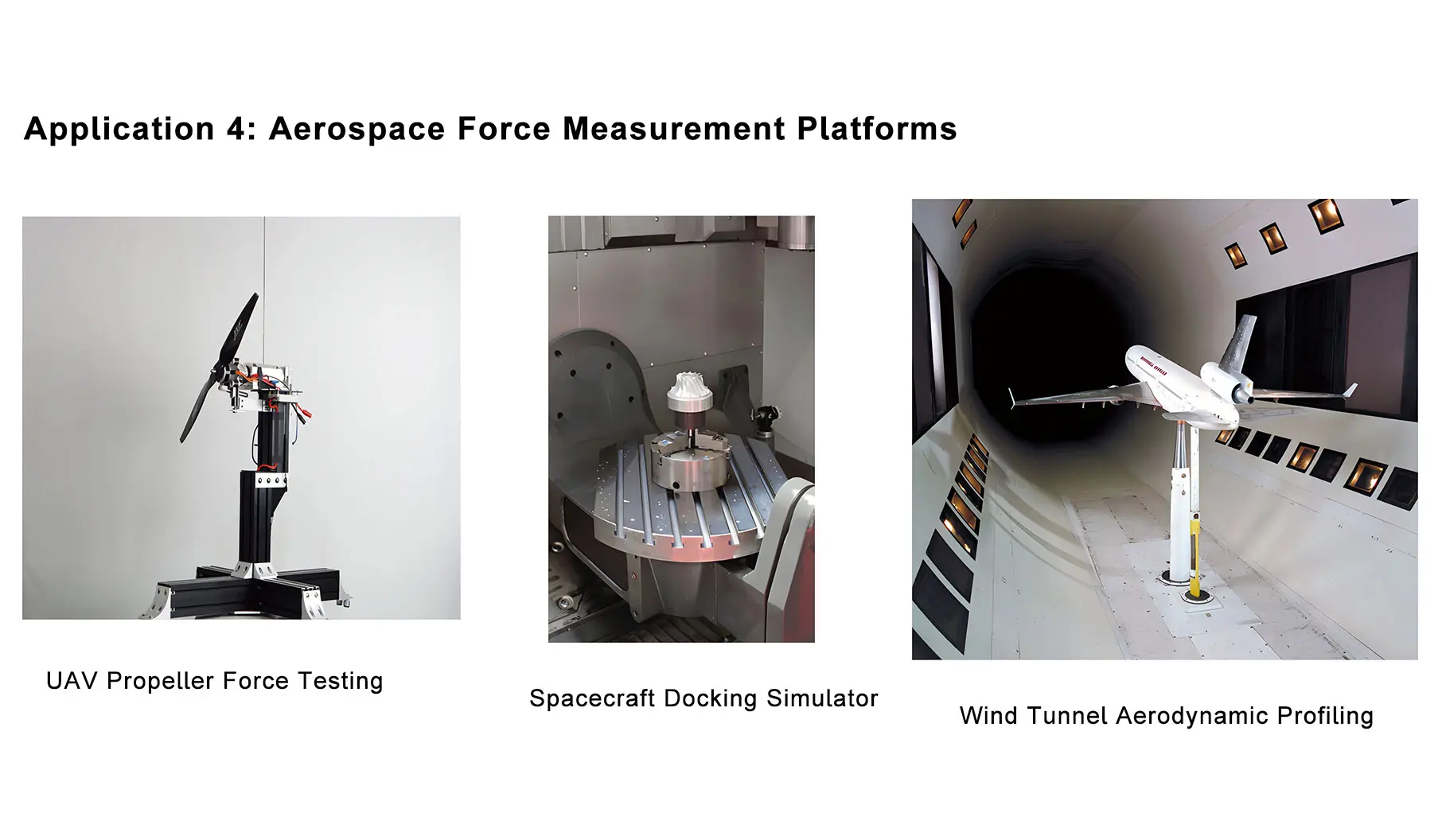

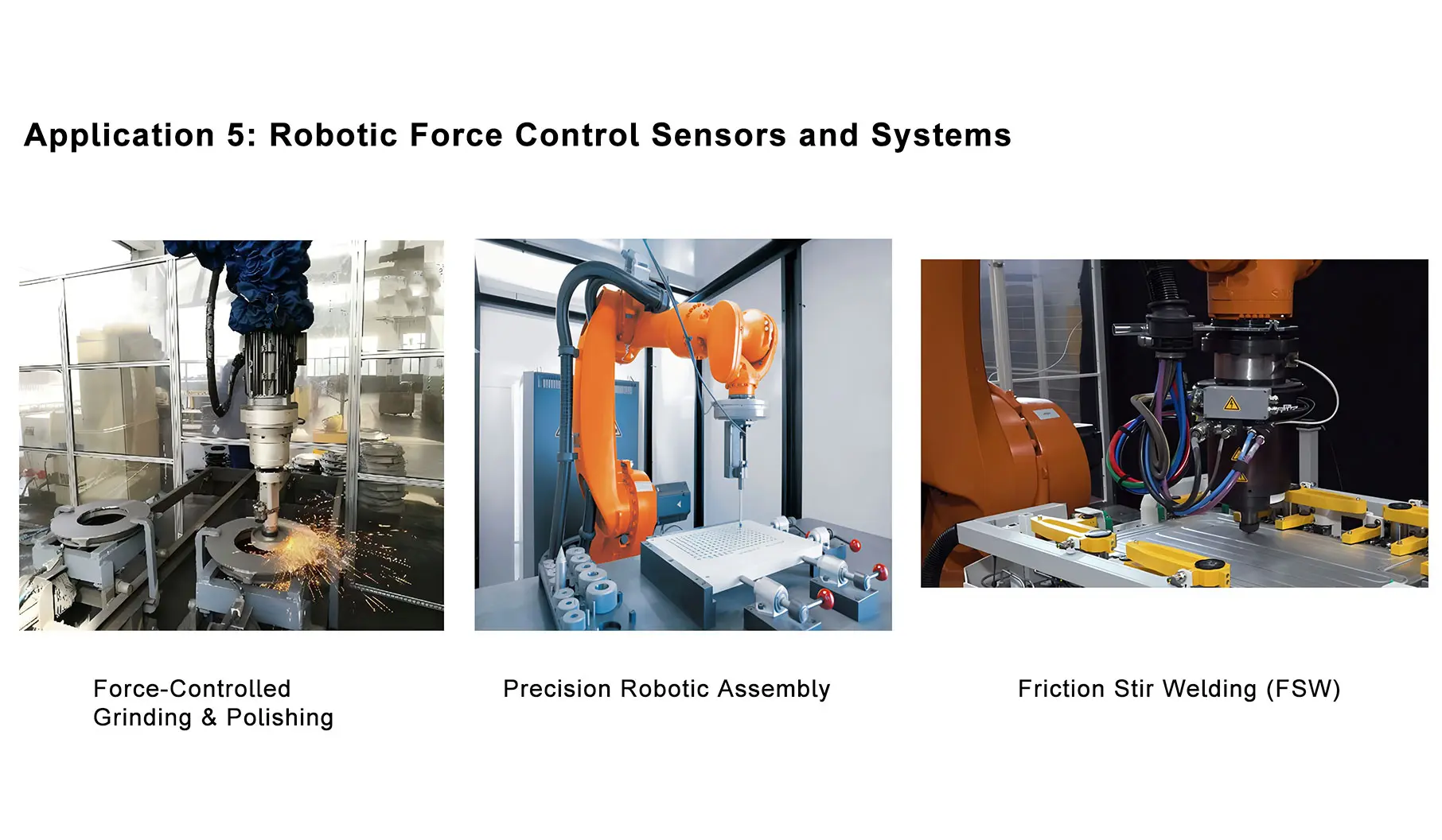

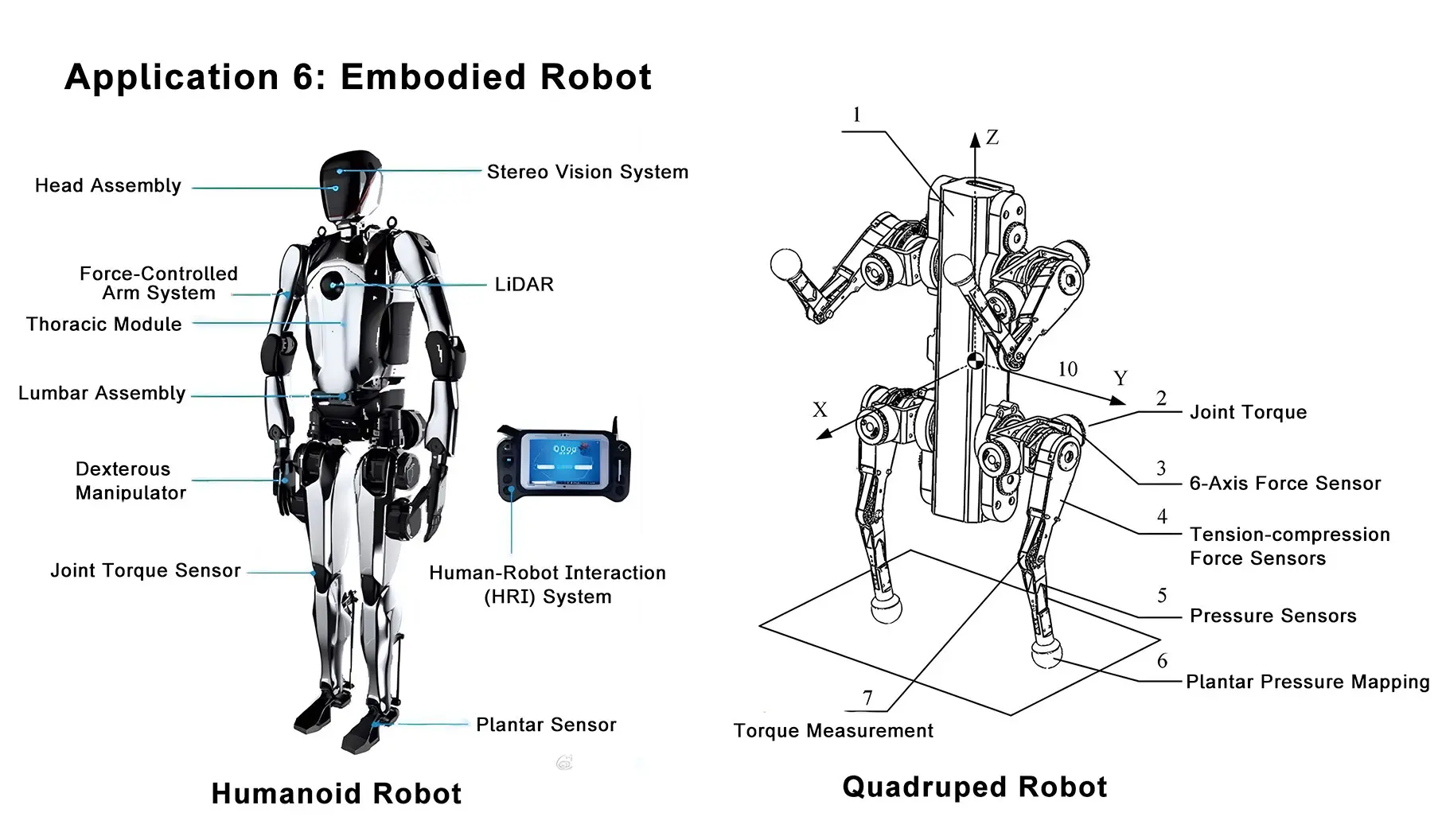

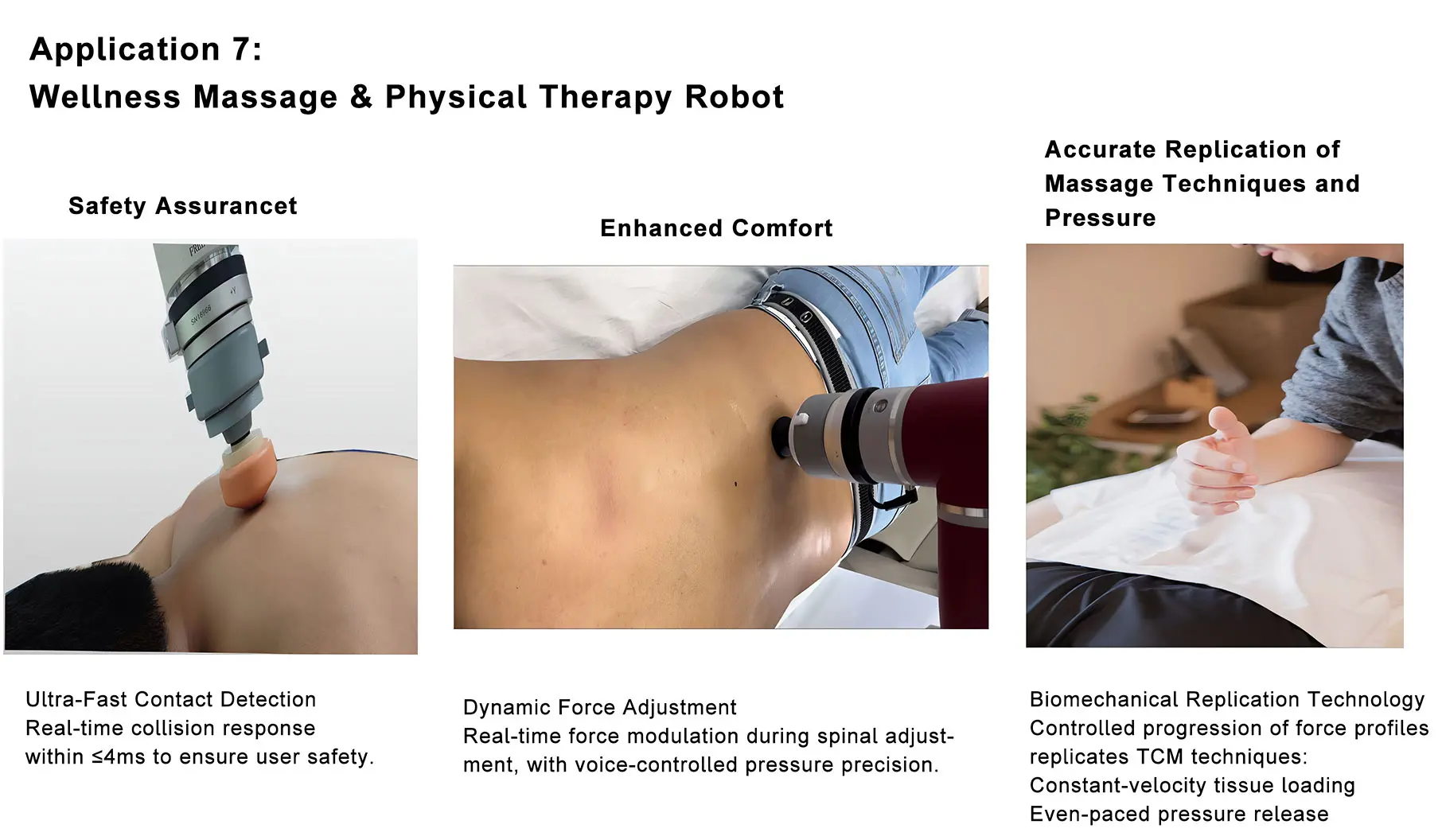

MareX provides multi-axis force sensors (including 2D, 3D, and 6D force sensors), load cells of various diameters (measuring compression force, tension/compression force), torque sensors, and various custom force sensors. These are widely applied in robotic operating systems across diverse fields such as aerospace technology, automotive components, rail transportation, consumer electronics, food and life sciences, warehousing and logistics, rubber and plastics, stone and wood processing, forging and casting, metal processing, and other non-standard automation. They provide crucial technical support for enhancing robotic operation accuracy and the precision/continuity of movements.

MareX sensors can be extensively applied to material handling robots (palletizing, loading/unloading, gripping, packaging, etc.), production processing robots (cutting, grinding, polishing, engraving, etc.), assembly robots, and welding robots. Among these, a significant portion of assembly robot tasks involves shaft-hole assembly, which requires the robot to possess motion compliance. Active compliance adjusts the movement of the robot’s end-effector based on feedback from sensors, while passive compliance utilizes unpowered mechanisms to control the motion of the gripper to compensate for positional errors.

Applications

MareX Sensors

Which sensor is right for you?

Keep Exploring MareX’s Sensors

MareX Custom Force Sensors: Precision Engineered for Your Needs

Choose from our sensors with standard configurations, or contact us for fully custom-engineered solutions.