Your Trusted Force Sensor Partner – Precision Engineered by MareX

Delivers comprehensive robotic software and hardware solutions.

Precision.Intelligent. MareX Sensor Customization Specialist

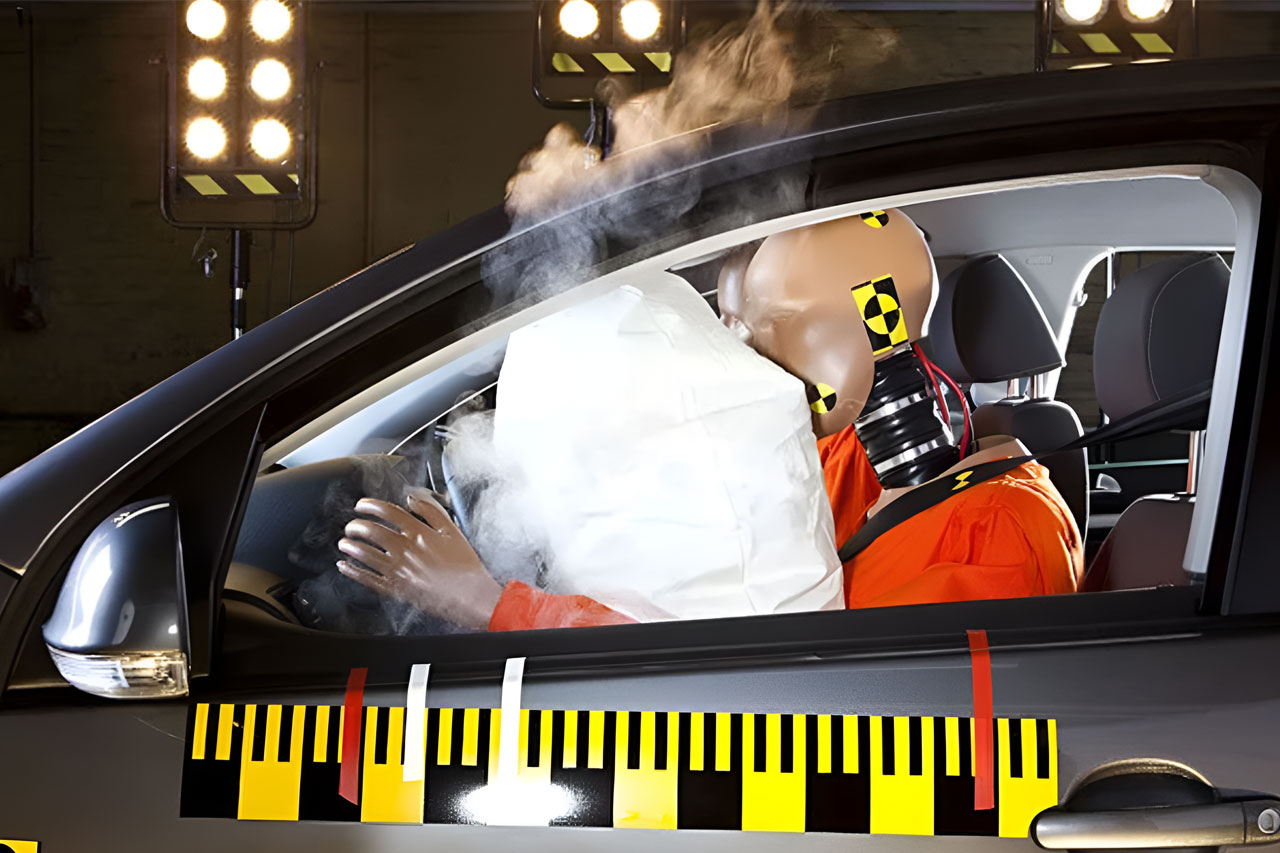

Automotive Manufacturing Assembly & Testing

Precision Assembly Assurance

Miniature force/torque sensors enable micron-level alignment accuracy. Reduce component damage by 37% in automated production lines

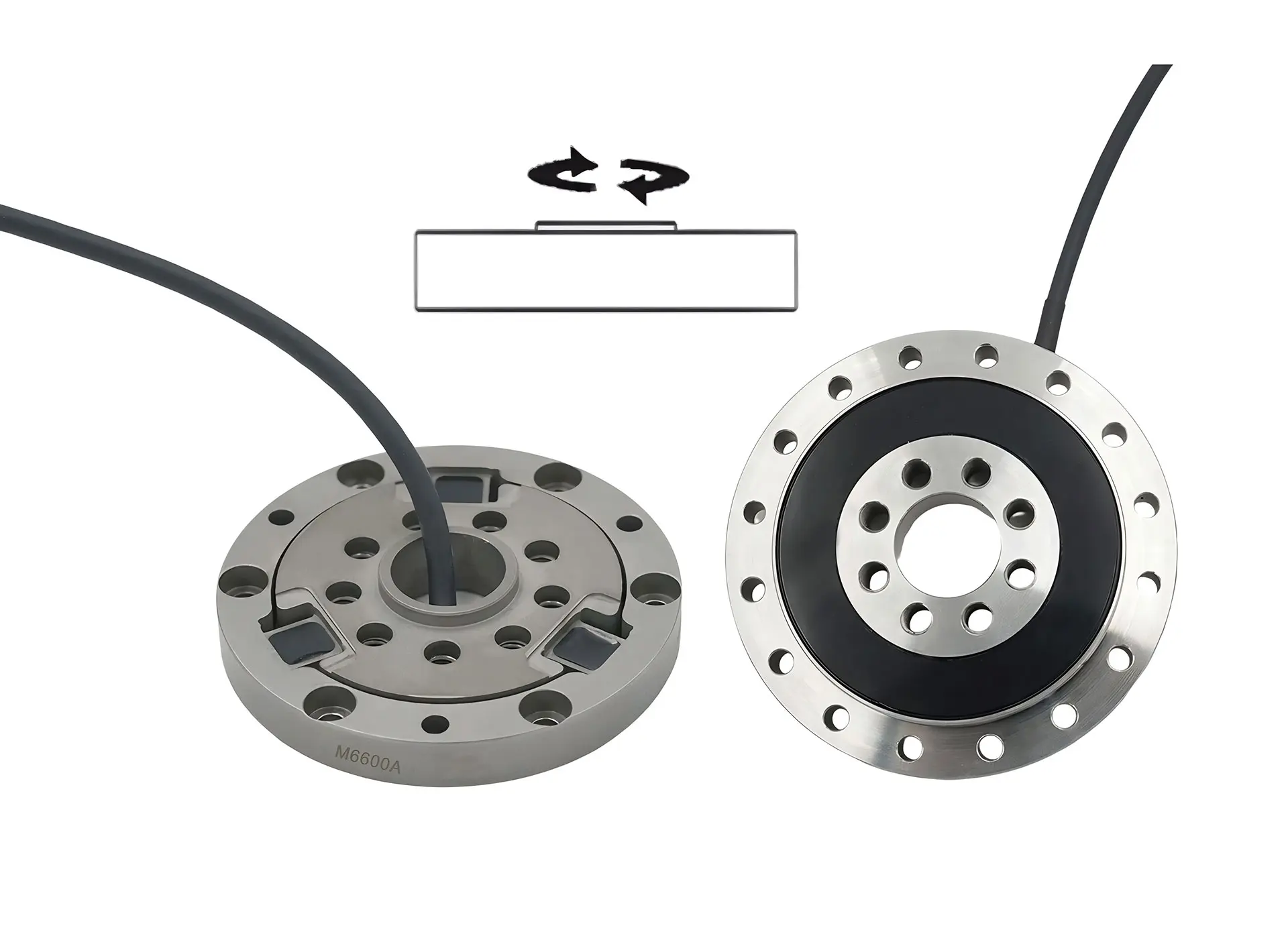

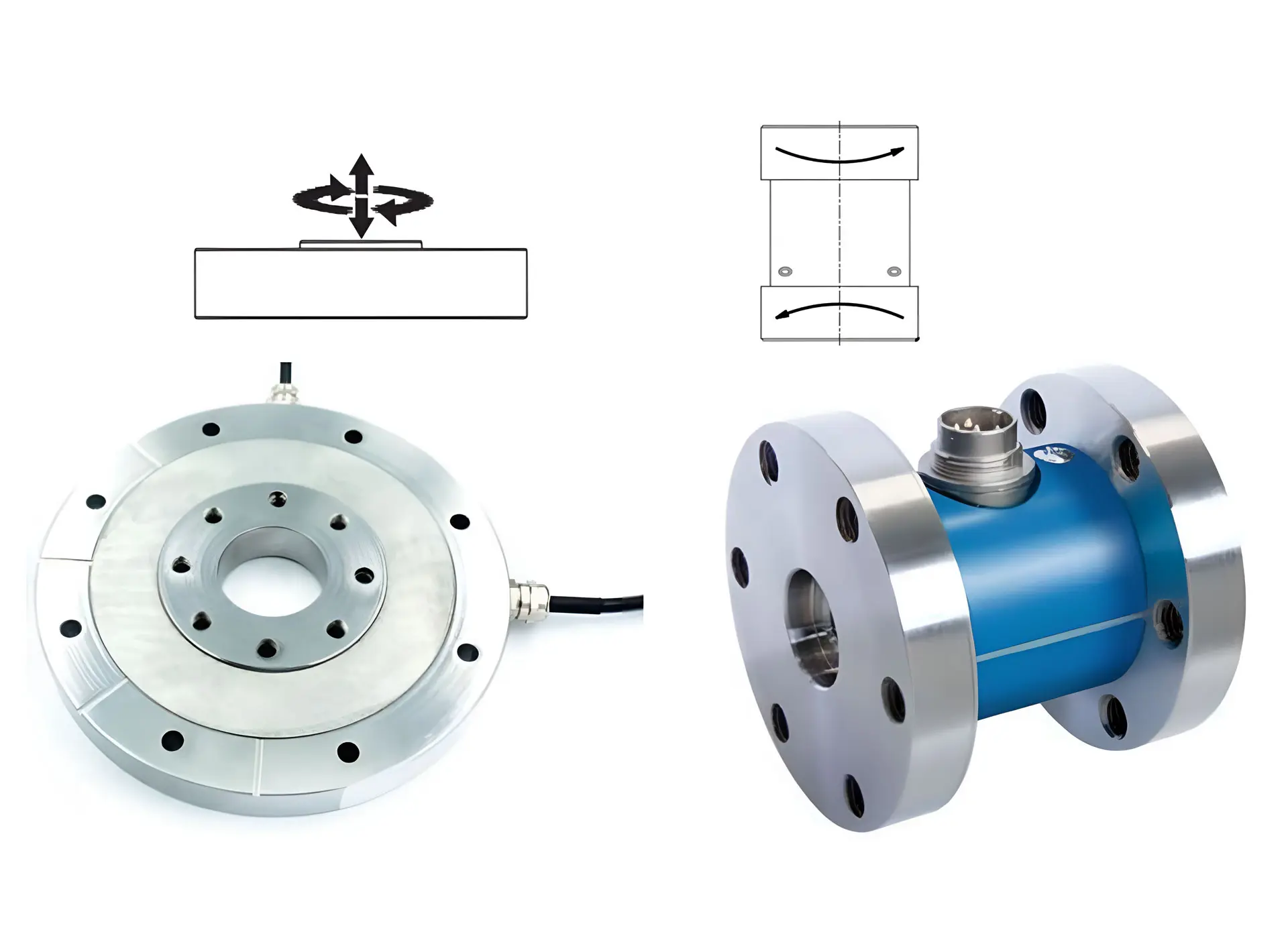

Efficient Multi-Test Integration

3D force sensors consolidate crash/body/seatbelt/brake validation. Cut testing cycles by 50% with parallel data acquisition

Predictive Quality Control

Real-time sensor analytics detect manufacturing deviations. Achieve 99.8% production consistency & 30% lower recalls

Regulatory Compliance Guarantee

High-fidelity impact sensors (20kHz sampling) capture crash dynamics. Deliver 100% FMVSS/NCAP certification success rate

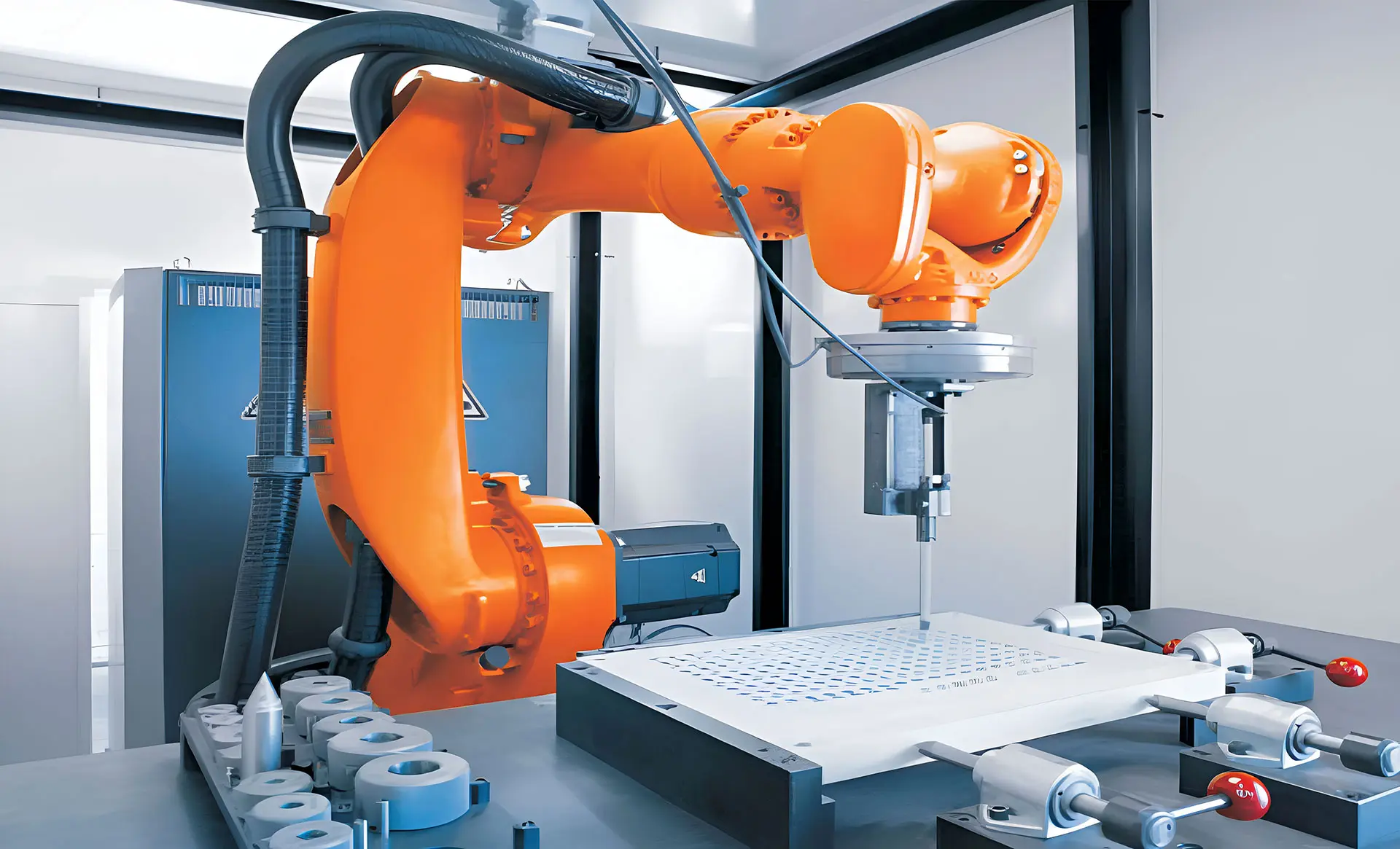

Industrial Control Automation

Multi-Industry Adaptability

Specialized sensors for extreme environments: -40°C to 150°C operation. Deployable in foundries/cleanrooms/space simulation chambers

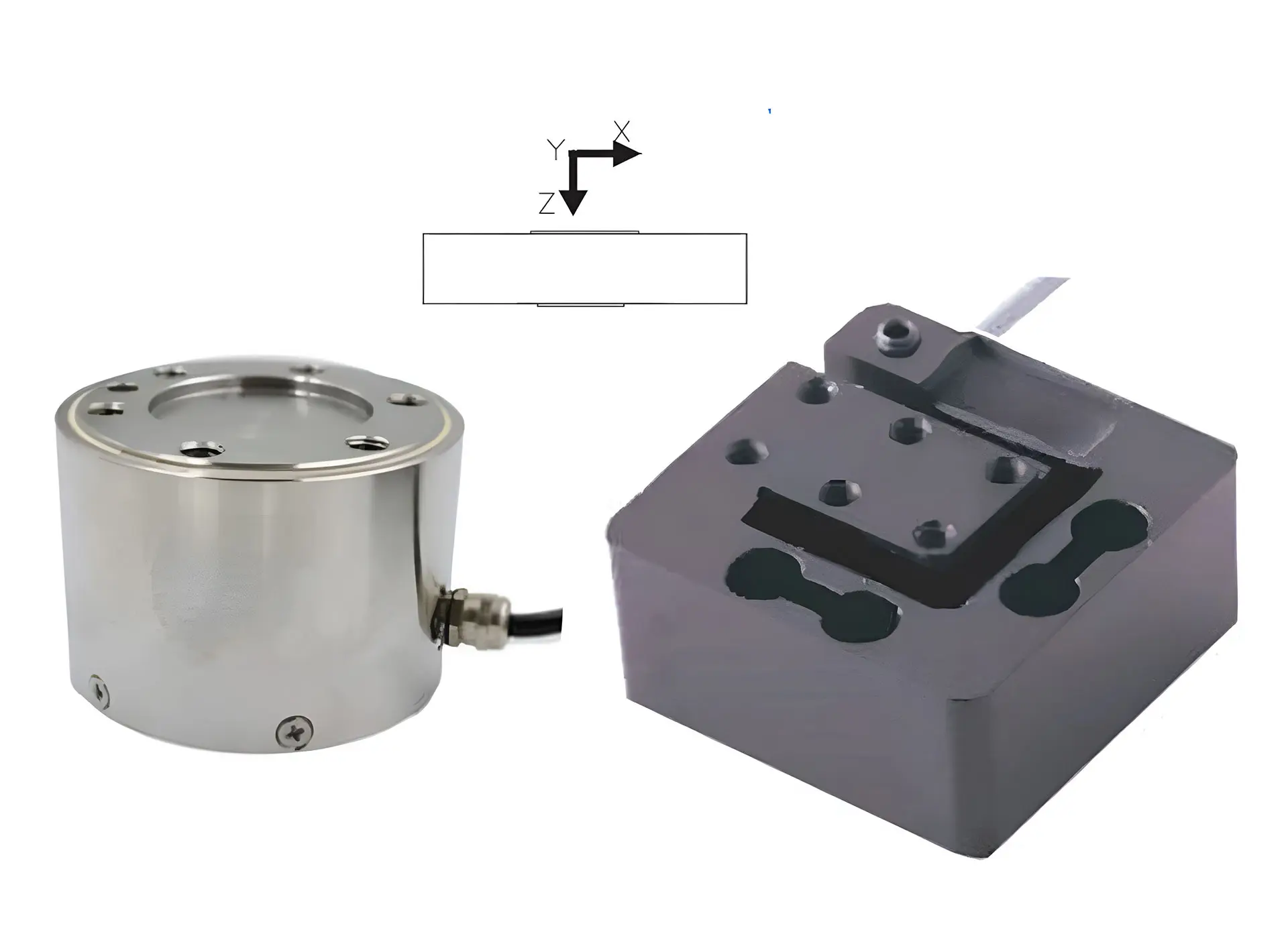

Precision Force Control

6-axis sensors enable ±0.02N resolution compliant motion. Achieve micron-level assembly accuracy in electronics manufacturing

Customization Capability

Non-standard load cells adapt to unique robotic end-effectors. Rapid prototyping for specialized gripping applications

Seamless System Integration

Real-time EtherCAT communication (2ms cycle time). Synchronize force feedback with robot path correction

Medical Applications

Regulatory Compliance Assurance

ISO certified sensors ensure traceable data integrity. Guarantee 100% audit-ready pharmaceutical documentation

Micro-Force Precision

0.001N-resolution monitoring for infusion/therapy devices. Achieve ±1% drug dosage accuracy in automated dispensing

Patient Safety Systems

Bed-mounted multi-axis sensors detect fall risks within 0.5s. Reduce clinical incident rates by 63% with real-time alerts

Sterile Environment Reliability

IP68-rated sensors withstand autoclave sterilization (135°C). Enable force-controlled surgical robotics in aseptic fields

MareX: Precision Engineered Force Intelligence for Tomorrow’s Automation

2000㎡

Factory Floor Area

60%

R&D Headcount Proportion

50+

Current Employee Count

MareX Details for professionals

MareX delivers intelligent robotic solutions that redefine precision automation for modern industries.

MAREX in the news

All the latest from MareX.

For More Custom Sensor’s Details

Frequently asked questions.

Consider: measurement range, accuracy, electrical interfaces, and applications (e.g., grinding, assembly). Please consult us directly.

Yes. Please contact us.

No. Sensors tolerate only occasional overloads.

1) Ground shielded wires of DAQ cards (M8128/M8126)

2) Lower sampling frequency

Use gravity compensation: pre-measure tool weight, center coordinates, and sensor zero point. Algorithms auto-compensate during operation.

Refer to academic papers.