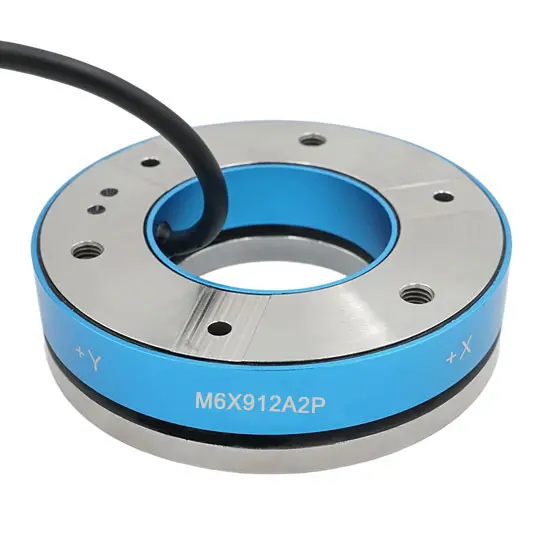

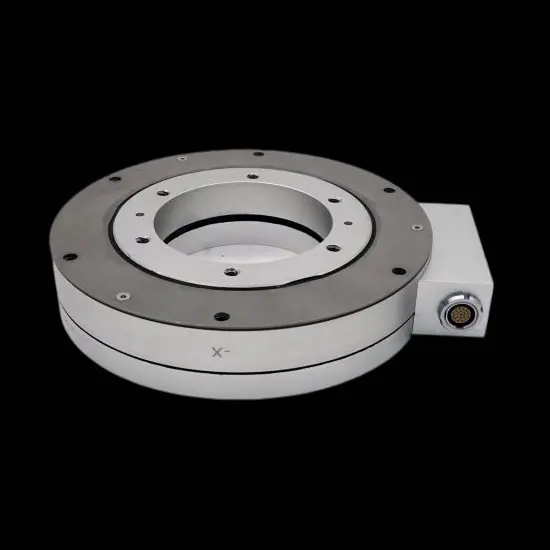

M6X9 Series 6-Axis Force Sensors

Matrix-decoupled

Matrix-decoupled M6X9 Series

Diameter range: 15–135mm

Force capacity: 50–6400N

Torque range: 0.5–320Nm

Matrix Decoupling Technology:

Nonlinearity & hysteresis: <0.5% F.S.

Cross-talk: <2% F.S.

300% overload protection

Environmental Resilience:

Standard: IP60

Optional: IP68 submersible (10m depth)

Integrated Electronics:

Built-in amplifier/data acquisition card options

Model. Which is best for you?

Our engineers possess decades of experience in sensor customization, delivering bespoke solutions tailored to your specifications. By analyzing your requirements for measuring ranges, dimensions, and accuracy, we develop optimized product designs that ensure seamless integration across diverse applications.

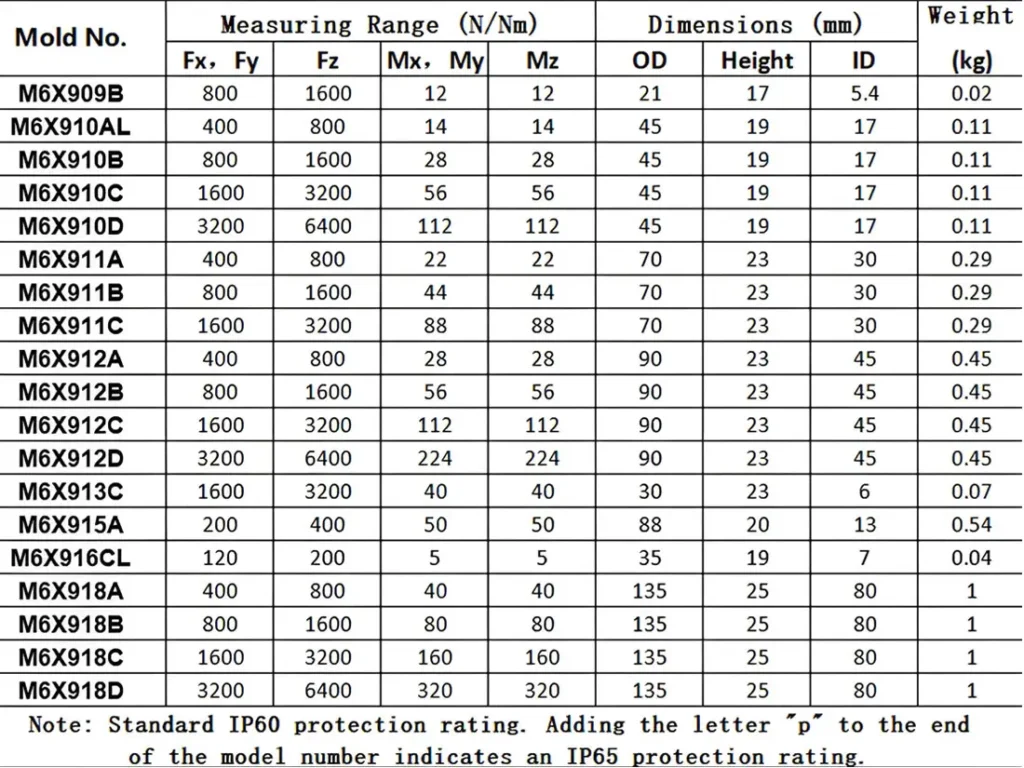

M6X9xx Series Products

MareX Sensor

Customization Specialist

6-Axis Force Sensors

9.2mm thickness, 3x overload capacity, IP60 protection

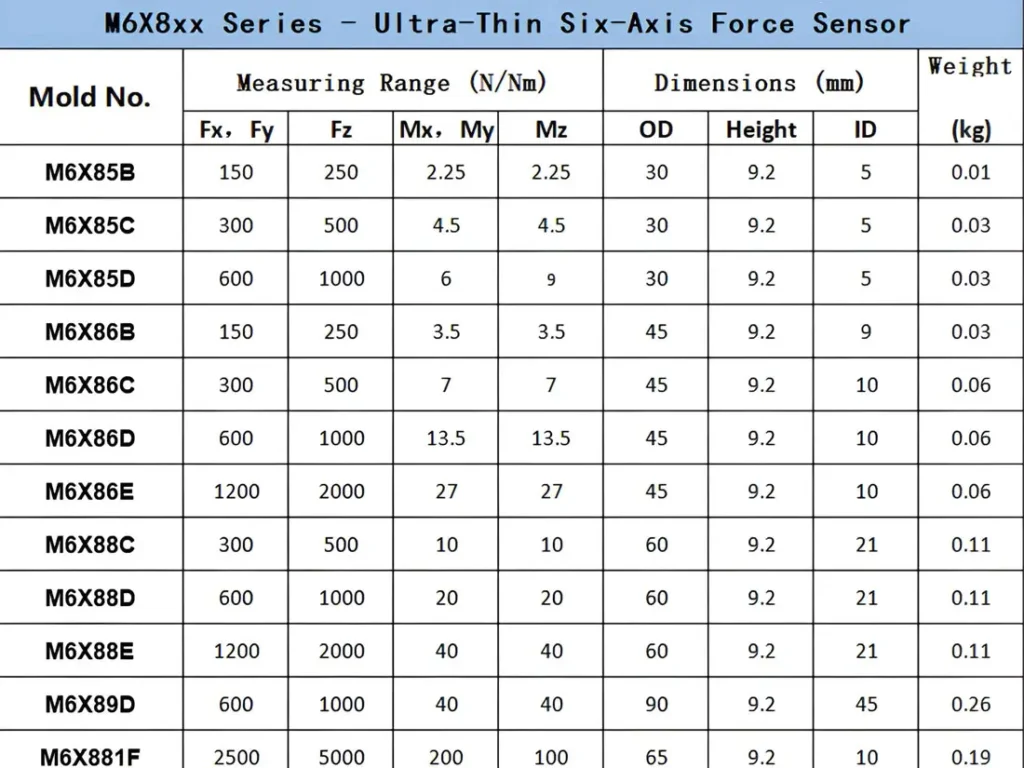

X8 Series Ultra-Thin 6-Axis Force Sensor feature a compact matrix-decoupled design with a thickness of just 9.2mm

Offering 3x overload capacity and IP60 protection

Delivering performance with nonlinearity and hysteresis below 1% F.S. and cross-talk under 3% F.S.

Robotic & General-Purpose Testing

The Series X9 matrix-decoupled 6-axis force sensors can amplifiers or data acquisition cards can be directly integrated into the sensor housing for compact system solutions.

Feature a diameter range of 15-135mm, force measurement capability from 50N to 6400N, and torque detection from 0.5Nm to 320Nm

Delivering high precision with nonlinearity and hysteresis below 0.5% F.S. and cross-talk under 2% F.S. Designed to withstand 3 times the rated load, these sensors come standard with IP60 protection and offer an optional IP68-rated submersible version (10-meter depth).

Low-range, high-precision industrial, 10× (or 6×) overload protection

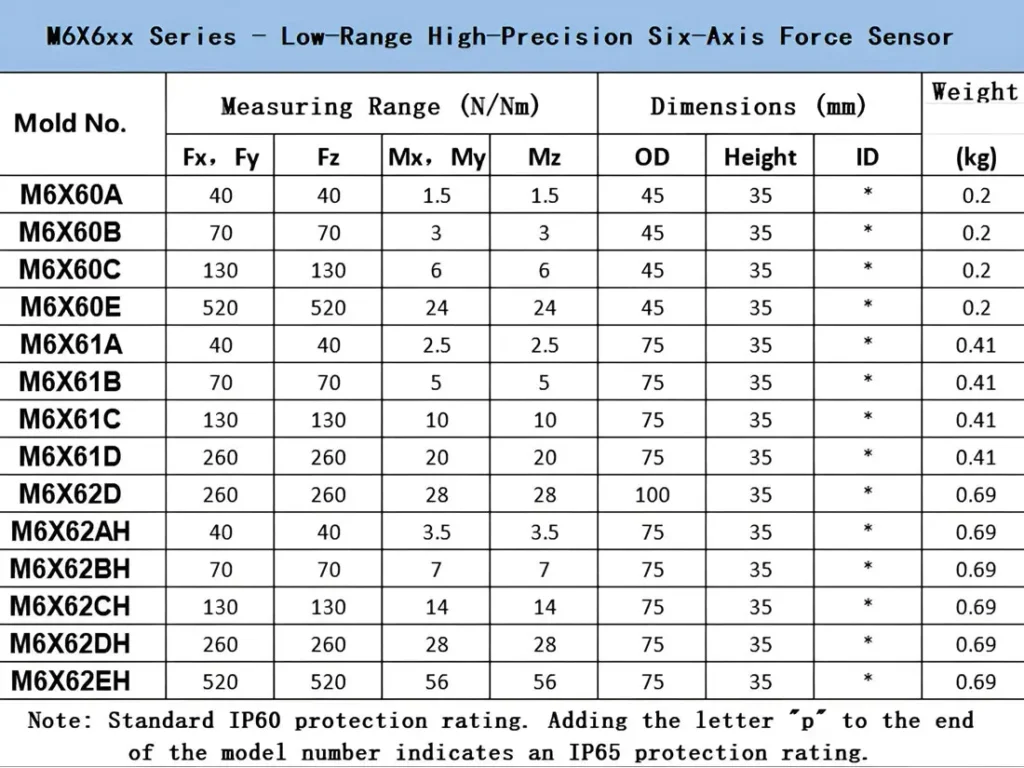

X6 Series low-range, high-precision industrial 6-axis force sensors employ matrix-decoupled technology, making them ideal for precision assembly and wind tunnel testing.

Provide 10× (or 6×) overload protection, IP60 or IP65 protection

Exceeding 75mm diameter supporting integrated amplifiers or data acquisition cards

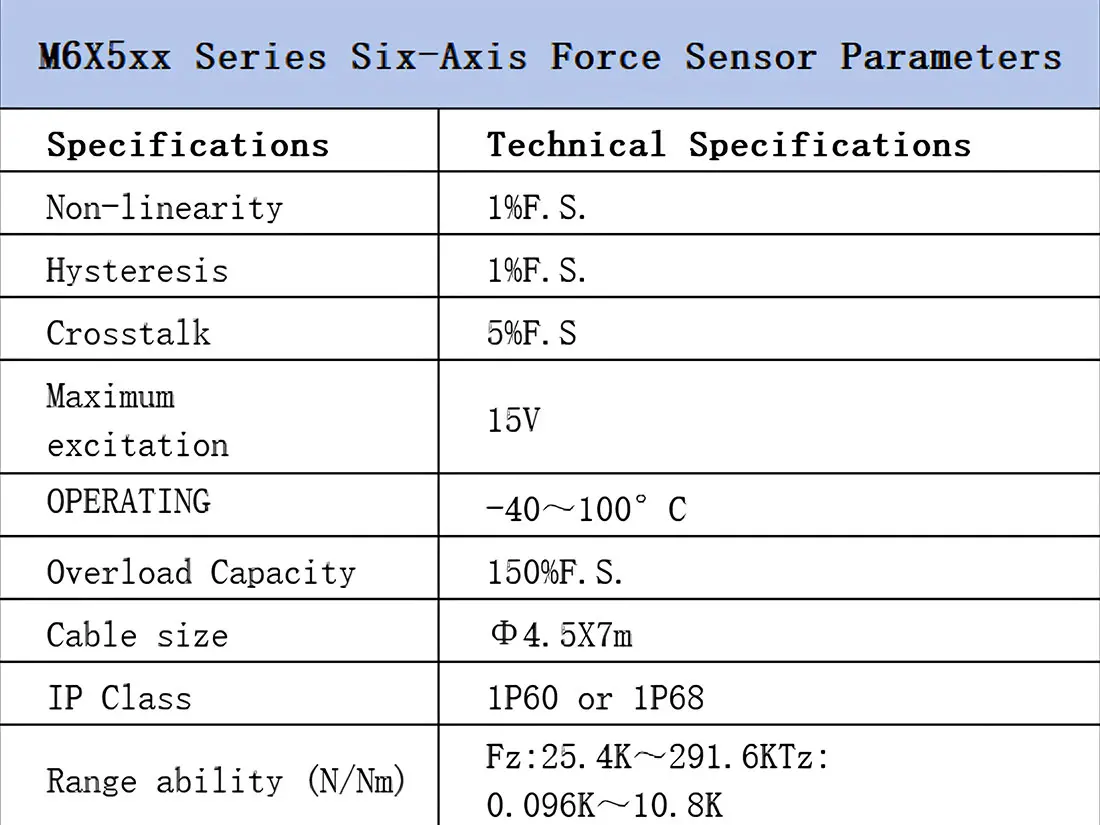

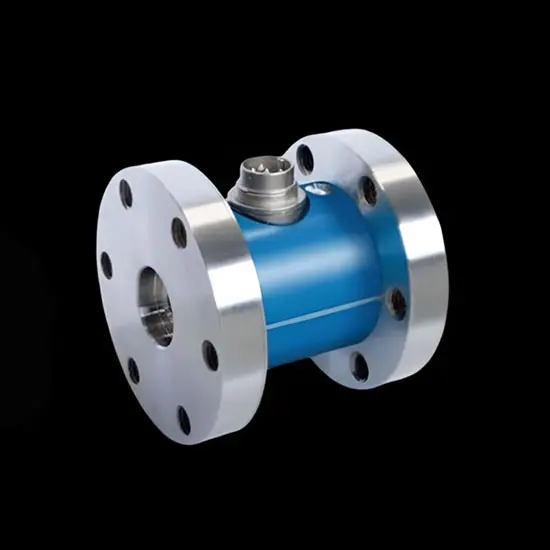

Maximum Range 291,600N, 2× overload, IP60 or IP68 protection

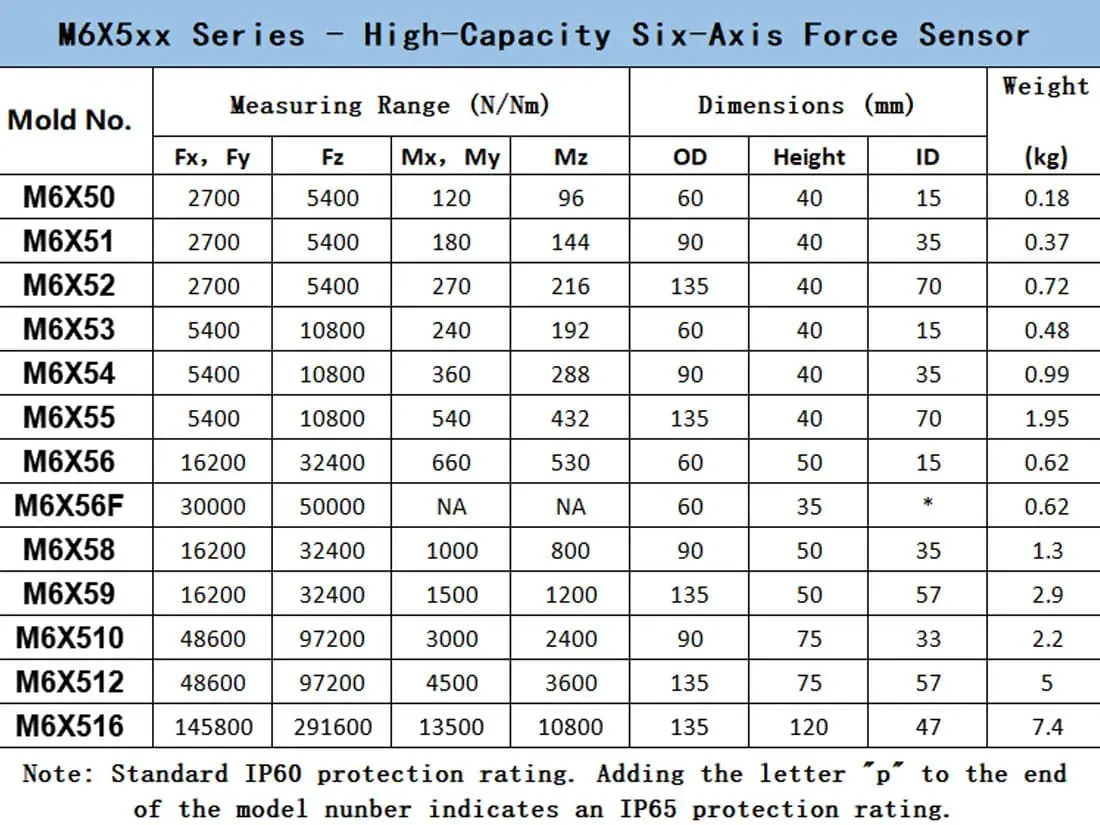

X5 Series high-capacity structurally decoupled 6-axis force sensors. Featuring a housing diameter range of 60–135mm and a maximum force capacity of 291,600N.

Withstand 2× overload forces while maintaining precision. Standard IP60 protection ensures industrial durability, with optional IP68-rated submersible versions (10-meter water depth) available for extreme environments.

Deliver robust performance with nonlinearity and hysteresis below 1% F.S. and cross-talk under 5% F.S.

3-10x overload protection, IP65-rated environmental resistance

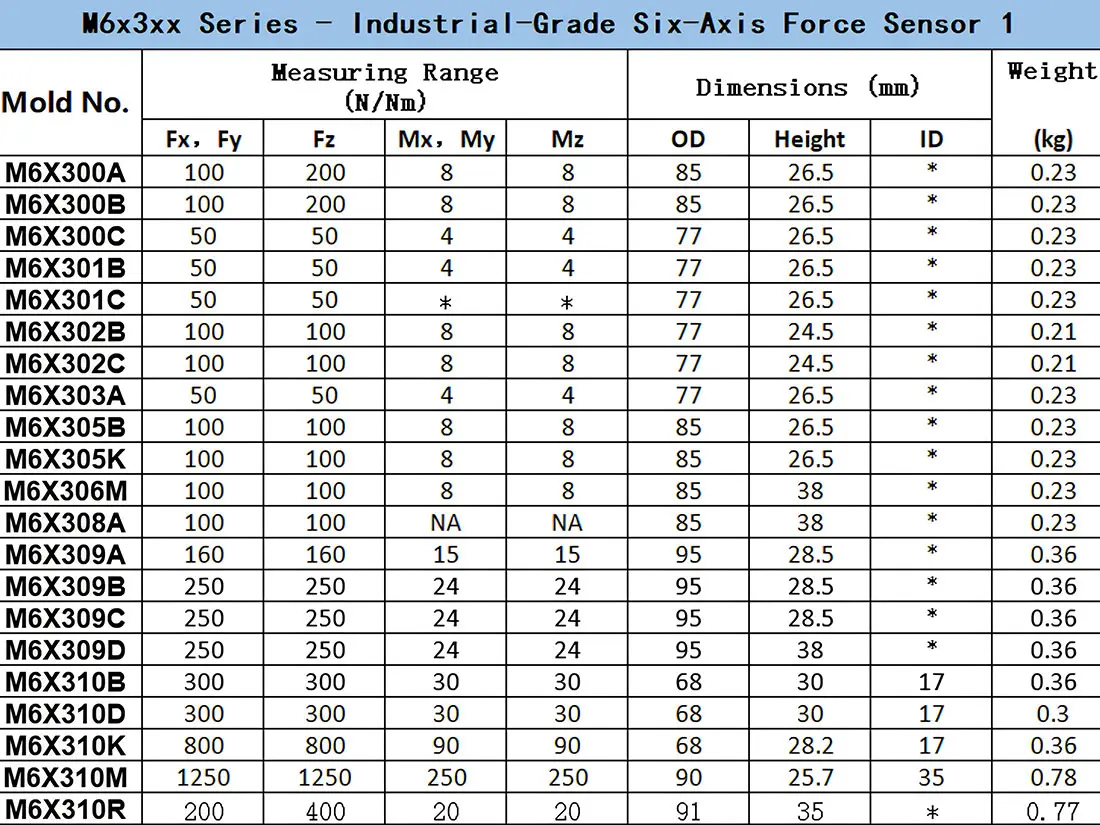

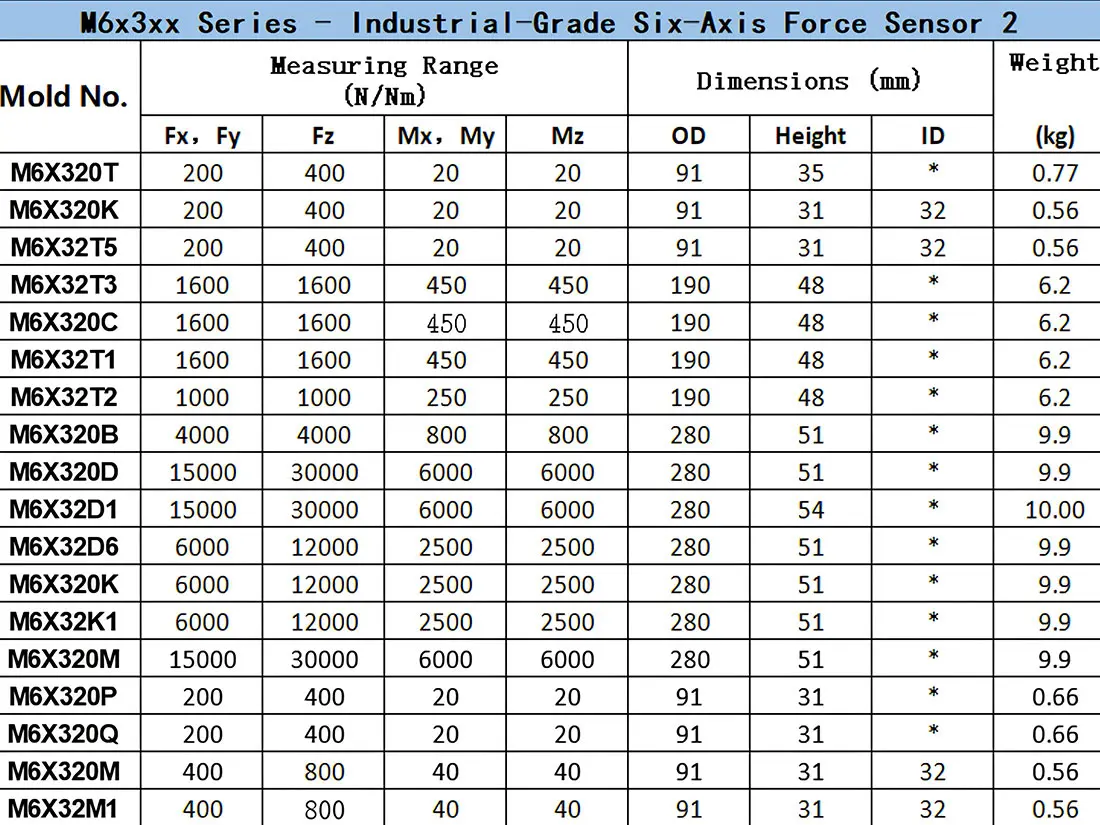

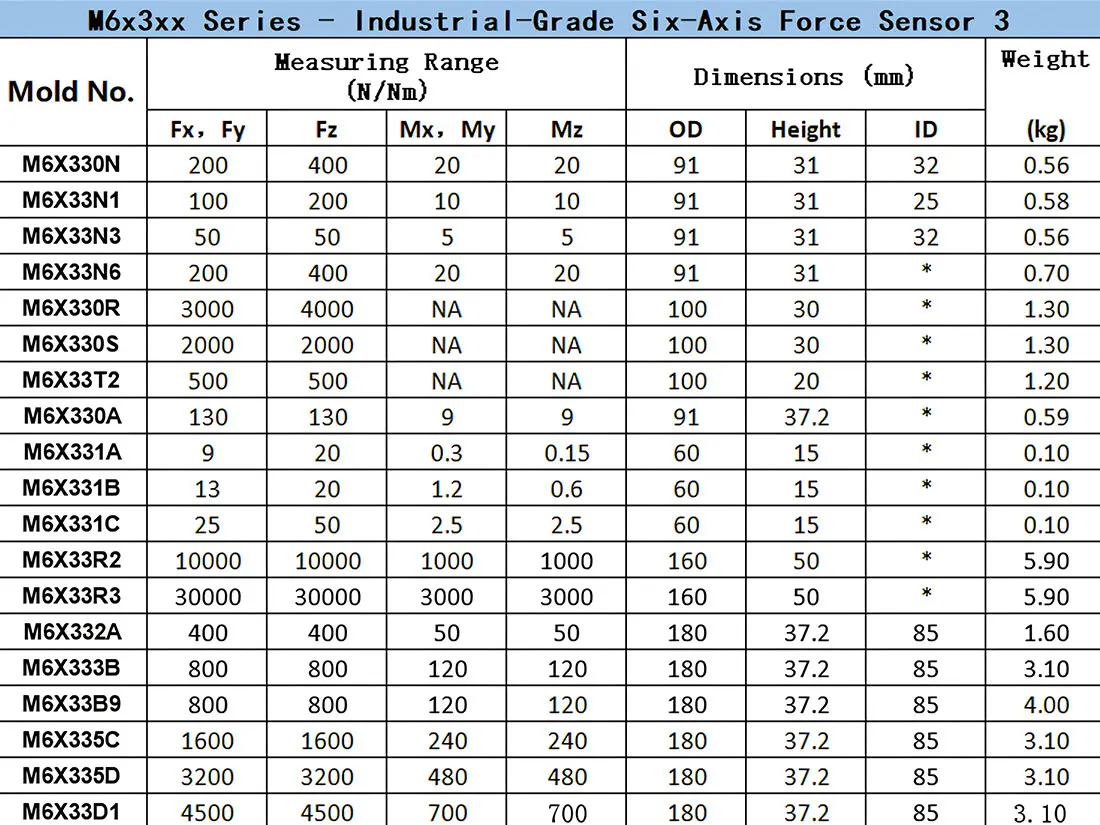

The X3 Series industrial-grade 6-axis force sensors ensuring reliable performance in demanding automation and robotics applications.

Provide 3-10x overload protection and IP65-rated environmental resistance integrating low-noise amplifiers for high-fidelity signal output.

Achieve nonlinearity and hysteresis below O.5% F.S.and cross-talk under 3%F.S.

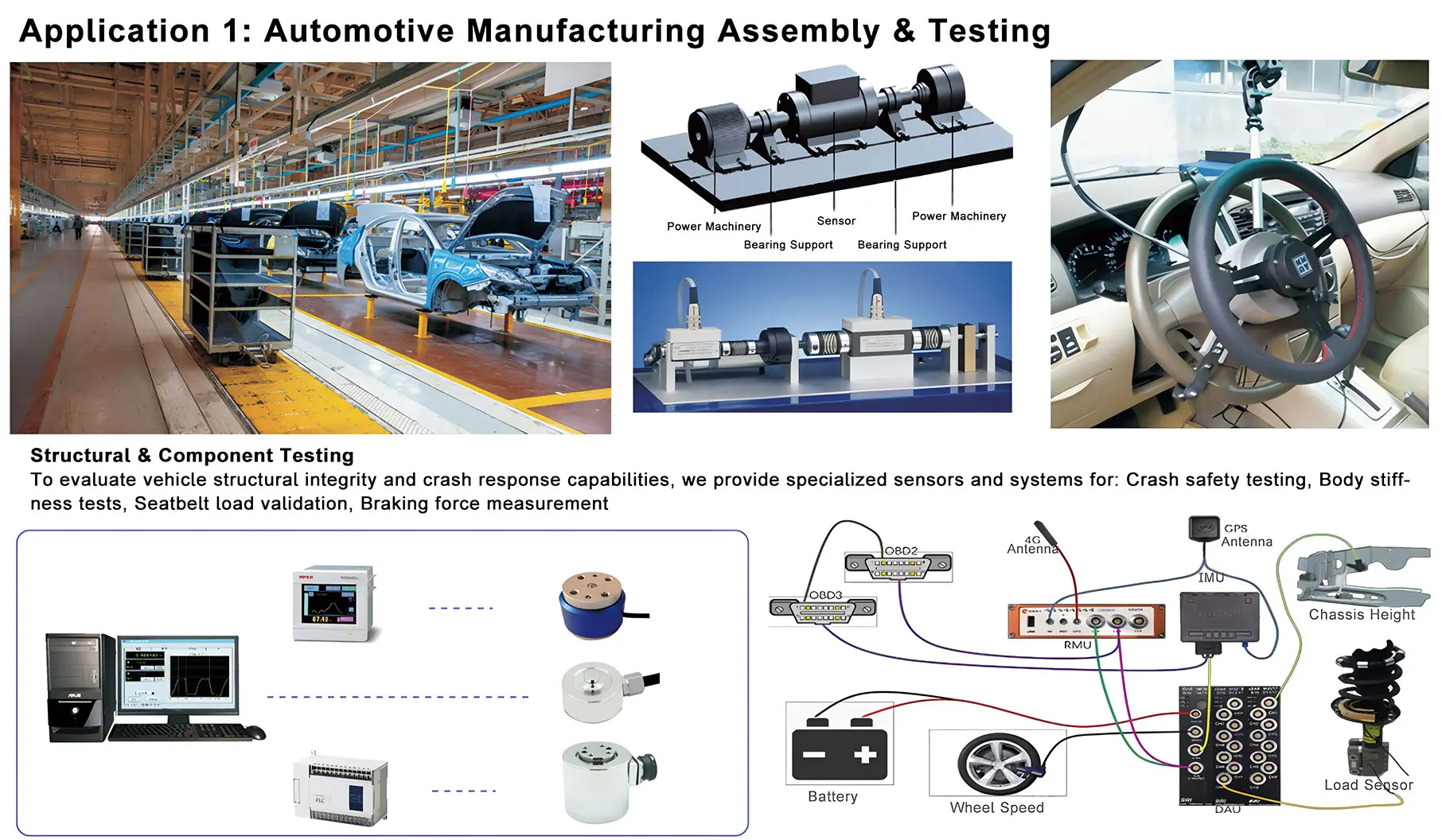

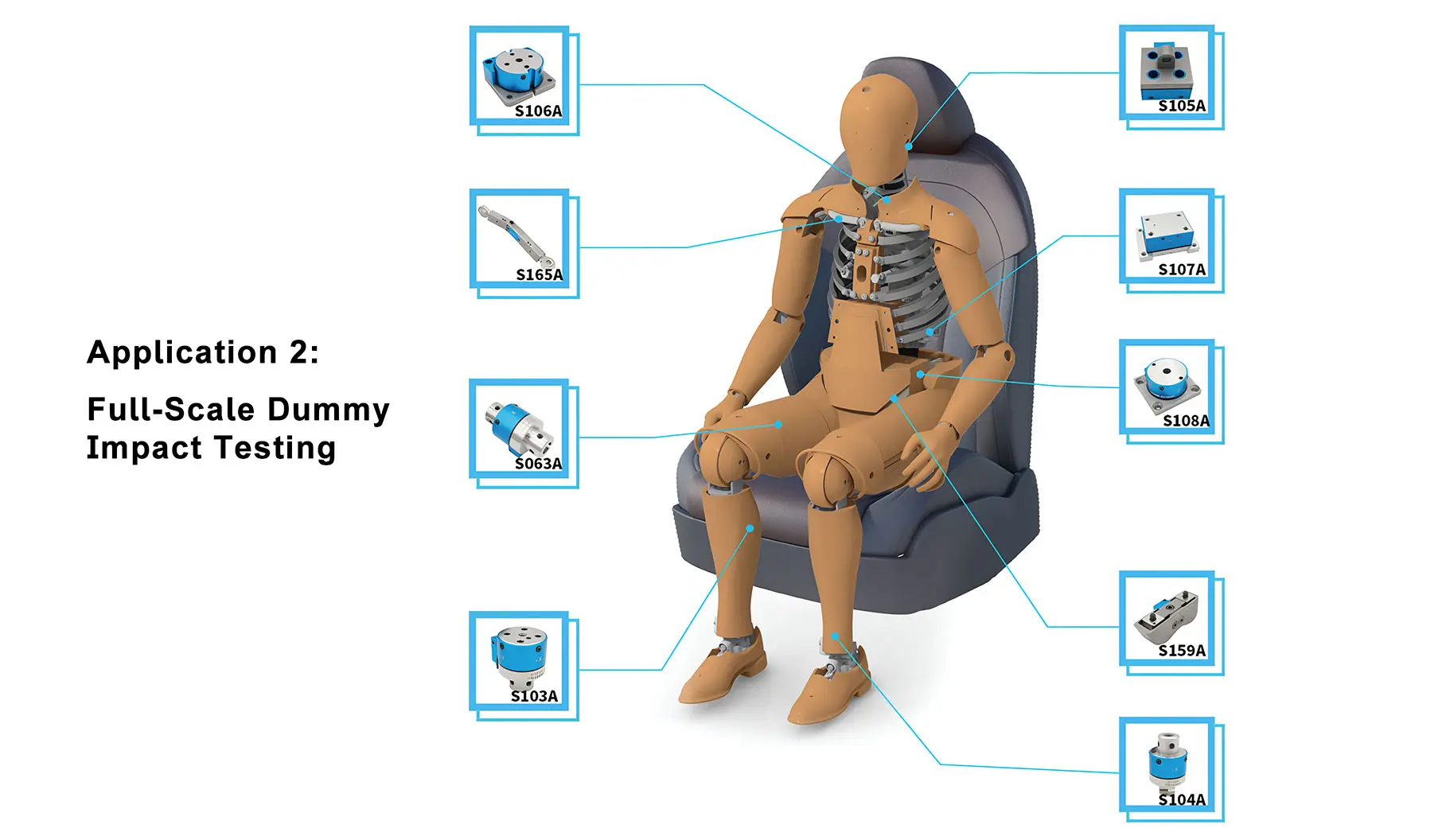

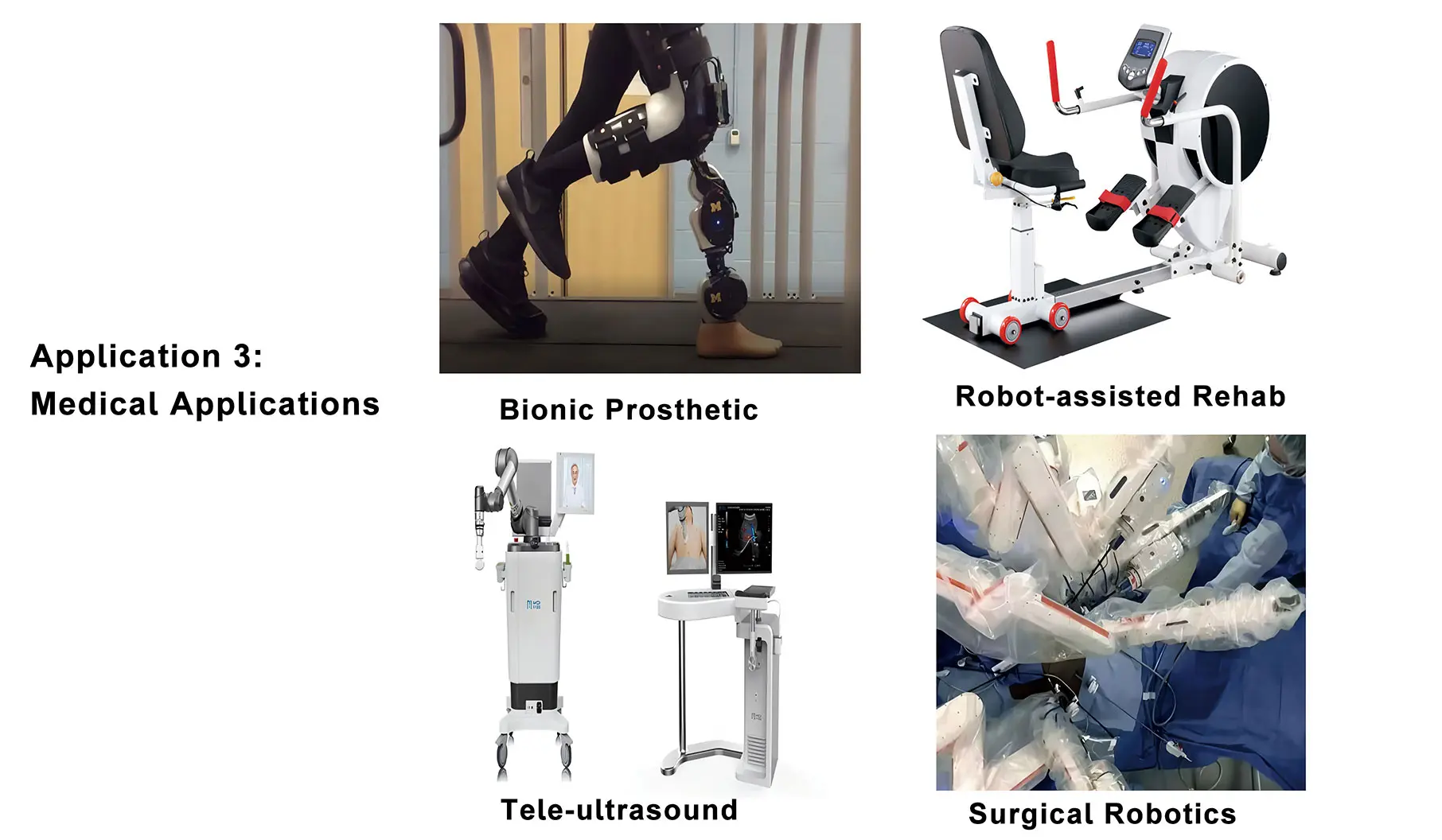

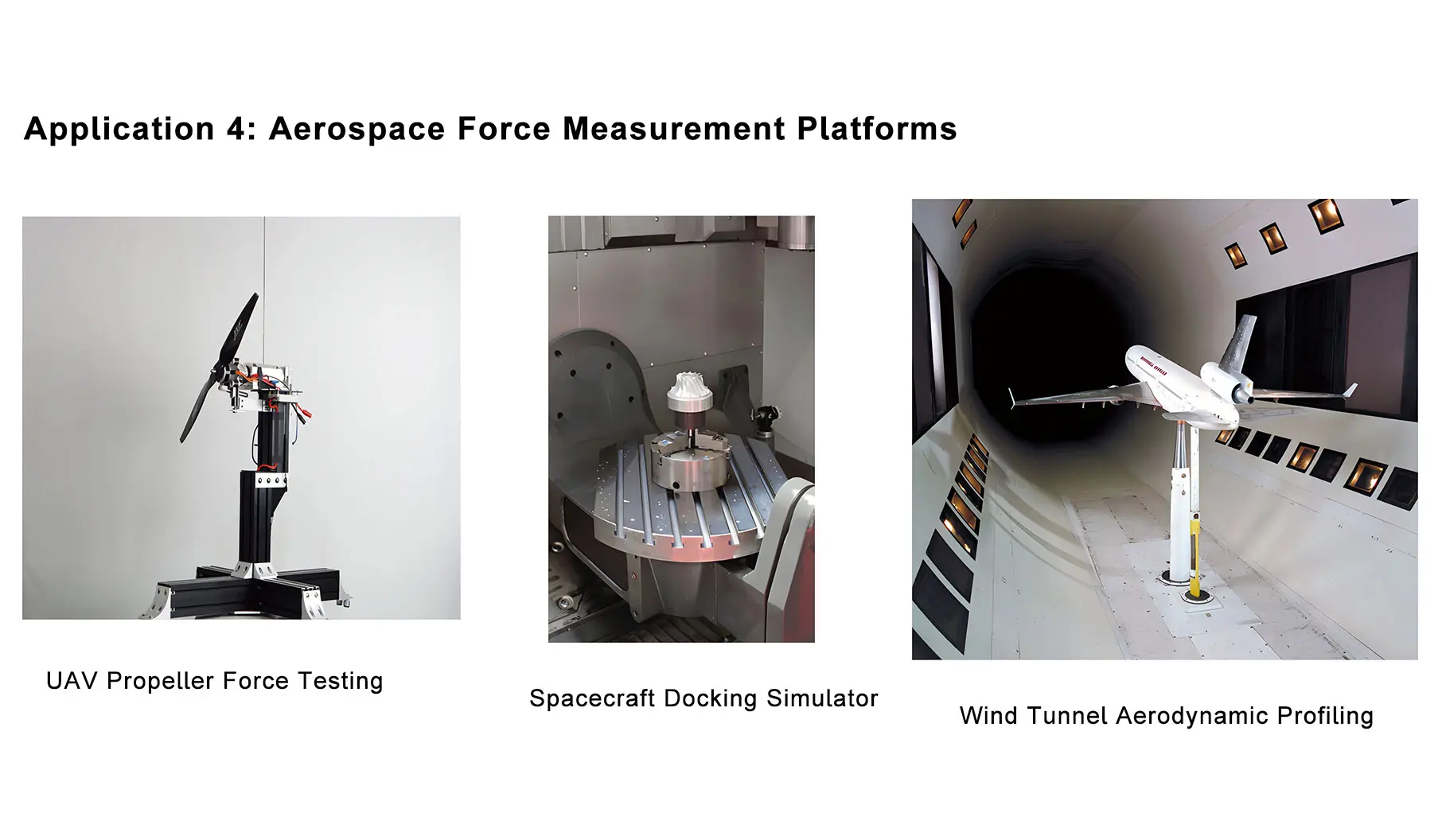

MareX Sensor, Versatile Applications.

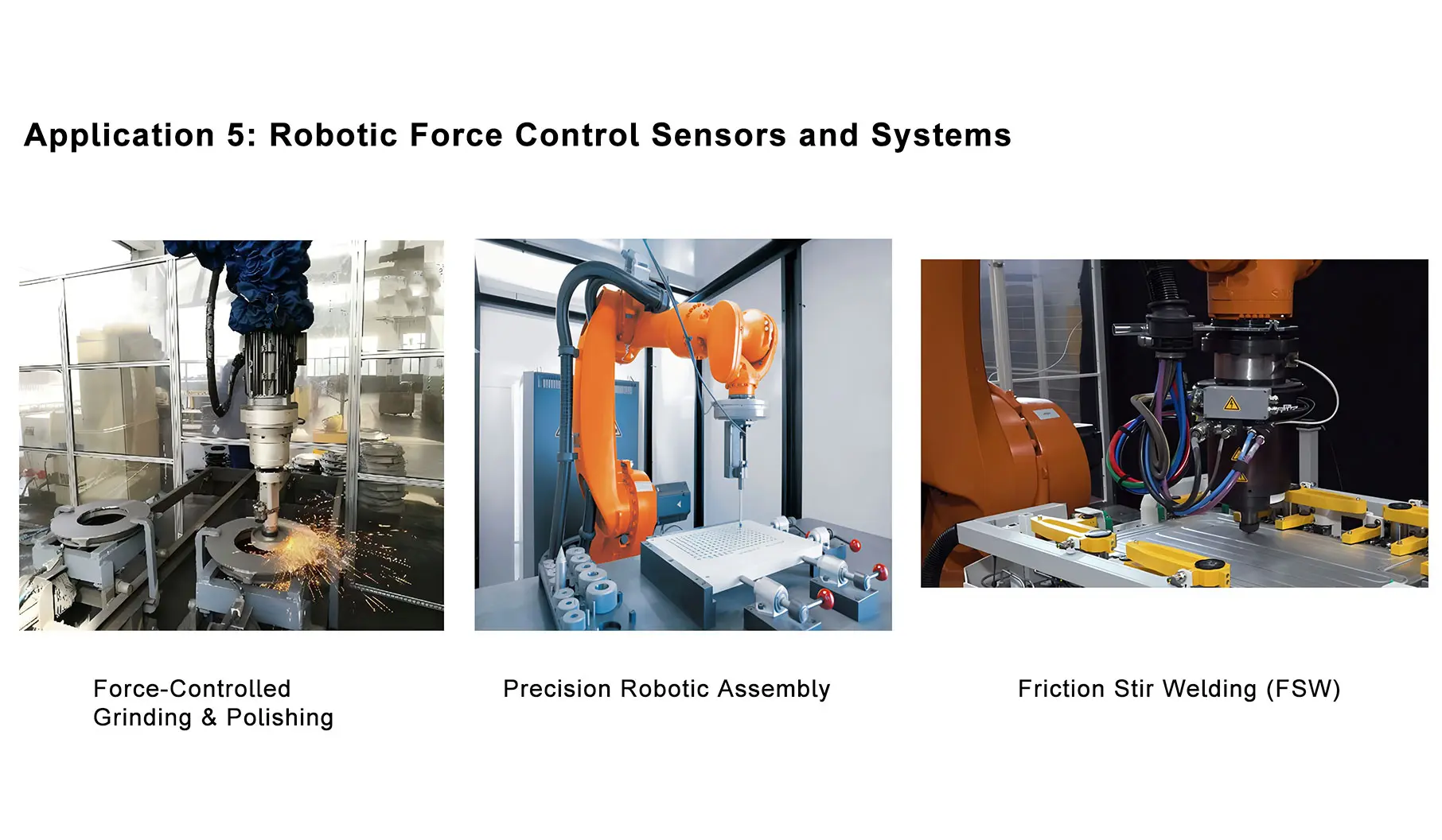

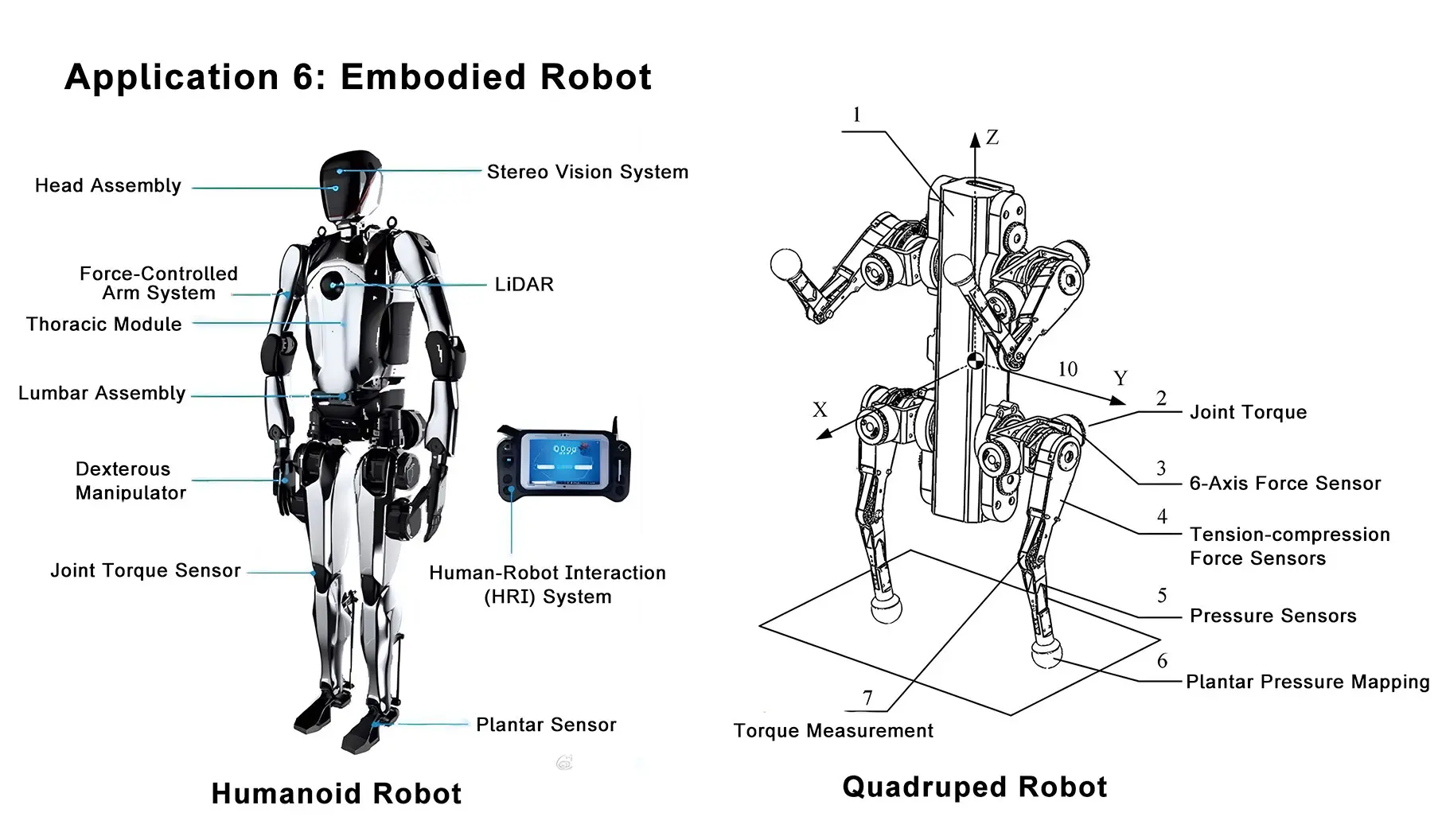

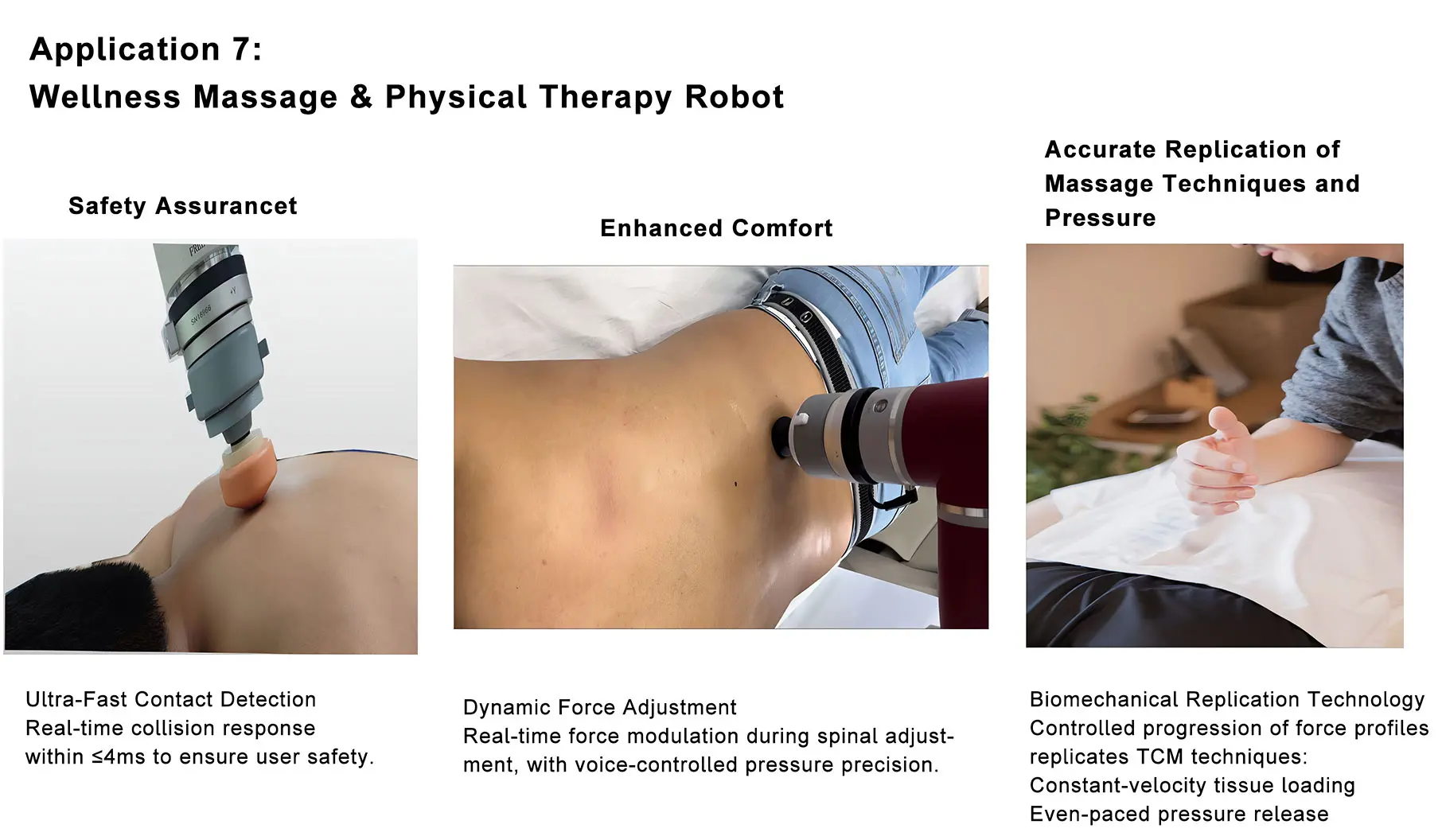

MareX provides multi-axis force sensors (including 2D, 3D, and 6D force sensors), load cells of various diameters (measuring compression force, tension/compression force), torque sensors, and various custom force sensors. These are widely applied in robotic operating systems across diverse fields such as aerospace technology, automotive components, rail transportation, consumer electronics, food and life sciences, warehousing and logistics, rubber and plastics, stone and wood processing, forging and casting, metal processing, and other non-standard automation. They provide crucial technical support for enhancing robotic operation accuracy and the precision/continuity of movements.

MareX sensors can be extensively applied to material handling robots (palletizing, loading/unloading, gripping, packaging, etc.), production processing robots (cutting, grinding, polishing, engraving, etc.), assembly robots, and welding robots. Among these, a significant portion of assembly robot tasks involves shaft-hole assembly, which requires the robot to possess motion compliance. Active compliance adjusts the movement of the robot’s end-effector based on feedback from sensors, while passive compliance utilizes unpowered mechanisms to control the motion of the gripper to compensate for positional errors.

Applications

MareX Sensors

Which sensor is right for you?

Keep Exploring MareX’s Sensors

MareX Custom Force Sensors: Precision Engineered for Your Needs

Choose from our sensors with standard configurations, or contact us for fully custom-engineered solutions.